Maintenance and care are important links to ensure the long-term and efficient operation of used water well drilling rigs.

First, regular inspection of equipment is basic maintenance work.

It is recommended to check the key components of the drilling rig, such as the drill bit, hydraulic system, and electrical system, before and after each use. Ensuring that these components are in good condition can reduce the probability of failure.

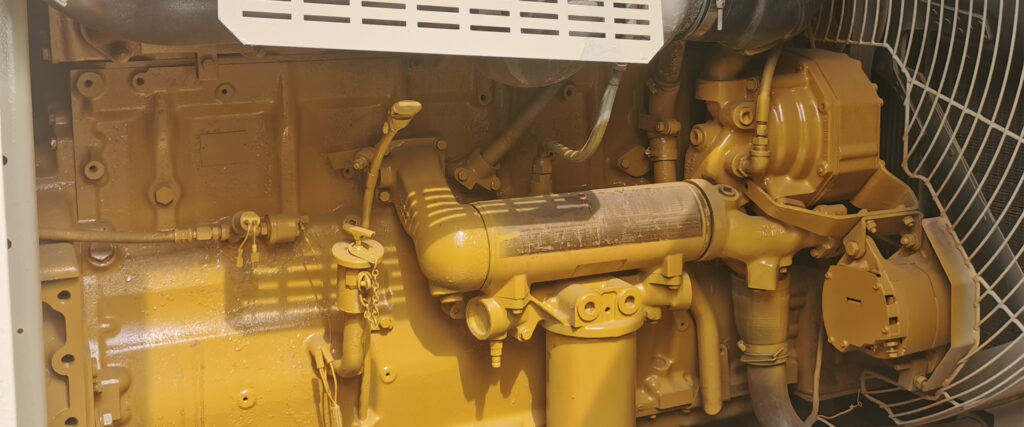

Second, keeping the equipment clean is an important measure to extend its service life.

During use, dirt and impurities may adhere to the equipment and affect its performance. Regular cleaning of the drilling rig, especially the drill bit and hydraulic system, can effectively avoid failures caused by dirt accumulation.

Third, lubrication is an important link that cannot be ignored in the maintenance process.

Regular lubrication of equipment with suitable lubricants can reduce friction, reduce wear, and thus extend the service life of the equipment. Make sure that the lubricant used meets the requirements of the equipment manufacturer to ensure the best results.

In addition, it is also wise to conduct professional technical inspections regularly.

You can ask professionals to conduct a comprehensive inspection of the equipment to detect potential problems in time and repair them. Regular professional maintenance can ensure that the equipment is always in optimal operating condition and avoid major failures caused by minor problems.

Finally, recording maintenance history is also an important good habit.

Recording each maintenance and maintenance can help you better understand the status and history of the equipment and facilitate future decision-making.

Through the above maintenance and maintenance tips, you can effectively extend the service life of the used water well drilling rig and ensure that it always maintains efficient and stable performance during work.